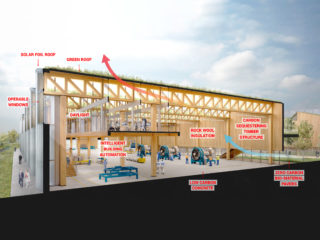

The aviation industry has resolved to reduce 50% of carbon emissions by 2050. Honoring that initiative, a new engine factory on the Airbus campus in Hamburg has been designed to be a model for sustainability in construction and manufacturing. The building is the product of a 10-year collaboration between Airbus and The Living. The design studio drew on its expertise in biology, computation, and sustainability to embed innovative solutions into every part of the project. The team used machine learning to generate design options that represent ideal combinations of the competing program goals, including input about employee work conditions, energy use, production flow, and future expansion. This data-driven approach for the triangular site created thousands of unique solutions that human ingenuity alone would not have conceived. The final result is a non-orthogonal plan that includes a courtyard, skylights, and a mezzanine that wraps around the production space. Featuring large windows that maximize daylight, the building is ventilated without the use of air conditioning. The construction incorporates low-carbon materials, such as CO₂-sequestering concrete, biobased cement, and sustainably harvested local timber. In the end, the building reduces carbon emissions by 48% compared to a standard factory. But more than that, it goes beyond typical factory parameters of production and cost to consider the employee experience and environmental impact across the lifespan of the building.

Project facts

Location Hamburg, Germany

Architect The Living

Airbus In-House Architect Bastian Schaefer

Year 2021

Category Commercial

AIANY Recognition

2022 AIANY Design Awards