< Read more from “Building Materials, Ancient to Future”

Last year, researchers at the University of Exeter in South West England announced they had successfully incorporated flakes of graphene into concrete. The result was twice as strong as traditional concrete, with half the mass. It’s just one of the many ways that scientists believe graphene will revolutionize architecture and construction.

Since its discovery in 2004, graphene has been touted as a “miracle” material. The substance, which is derived from graphite mined from the Earth, is stronger than steel and highly water-resistant, yet so lightweight it’s the only 2D material in the world. It also conducts heat and electricity efficiently. All that means graphene could enhance every element of buildings, including flood-proof foundations, highly fire-resistant walls, anti-corrosive paint, and solar roofs.

But, for all the buzz, the graphene-based house of the future doesn’t exist quite yet. That’s in part because researchers are still testing and developing graphene-enhanced building materials.

“There’s a huge gap between a research lab where someone says, ‘Aha, I’ve got a square centimeter of graphene-enhanced concrete that can stand up to something like a nuclear blast,’ and how in the world you mass produce that so it’s useful to somebody,” said Les Johnson, co-author of the 2018 book Graphene: The Superstrong, Superthin, and Superversatile Material That Will Revolutionize the World.

One day, adding the substance to fiberglass rebar and concrete for façades could decrease the amount of materials needed to construct a building—and ultimately, the project’s carbon footprint. Once those products become available on the market, though, it could still take some time before architects, builders, and local municipalities embrace them.

Terrance Barkan is the executive director of the Graphene Council, a network of universities and companies developing uses for graphene. “Until there have been tests done to meet all of the strength requirements, and graphene gets added to building code specifications,” he said, “no one’s going to build with it.”

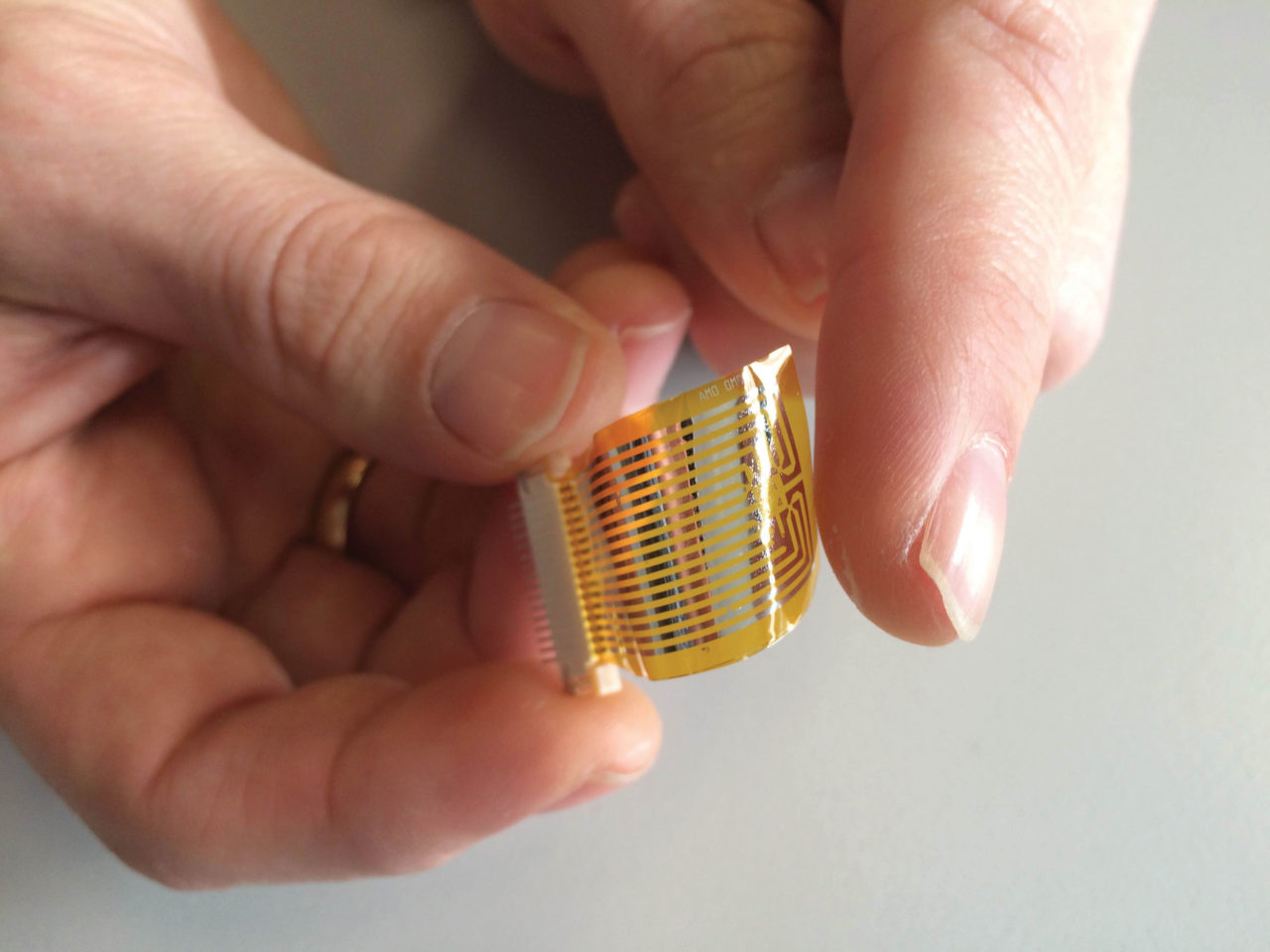

Another challenge is that scientists haven’t figured out how to mass produce continuous sheets of graphene yet; all the graphene that’s produced now is in the form of tiny flakes. But Johnson and his co-author, Joseph Meany, said that some of the most exciting innovations will require the material to be in sheet form. Meany imagines that when that happens, superthin layers of graphene could potentially be used to reinforce retaining walls, create entire walls that conduct electricity and insulate homes, and harness solar energy. But that technology is still a long way off.

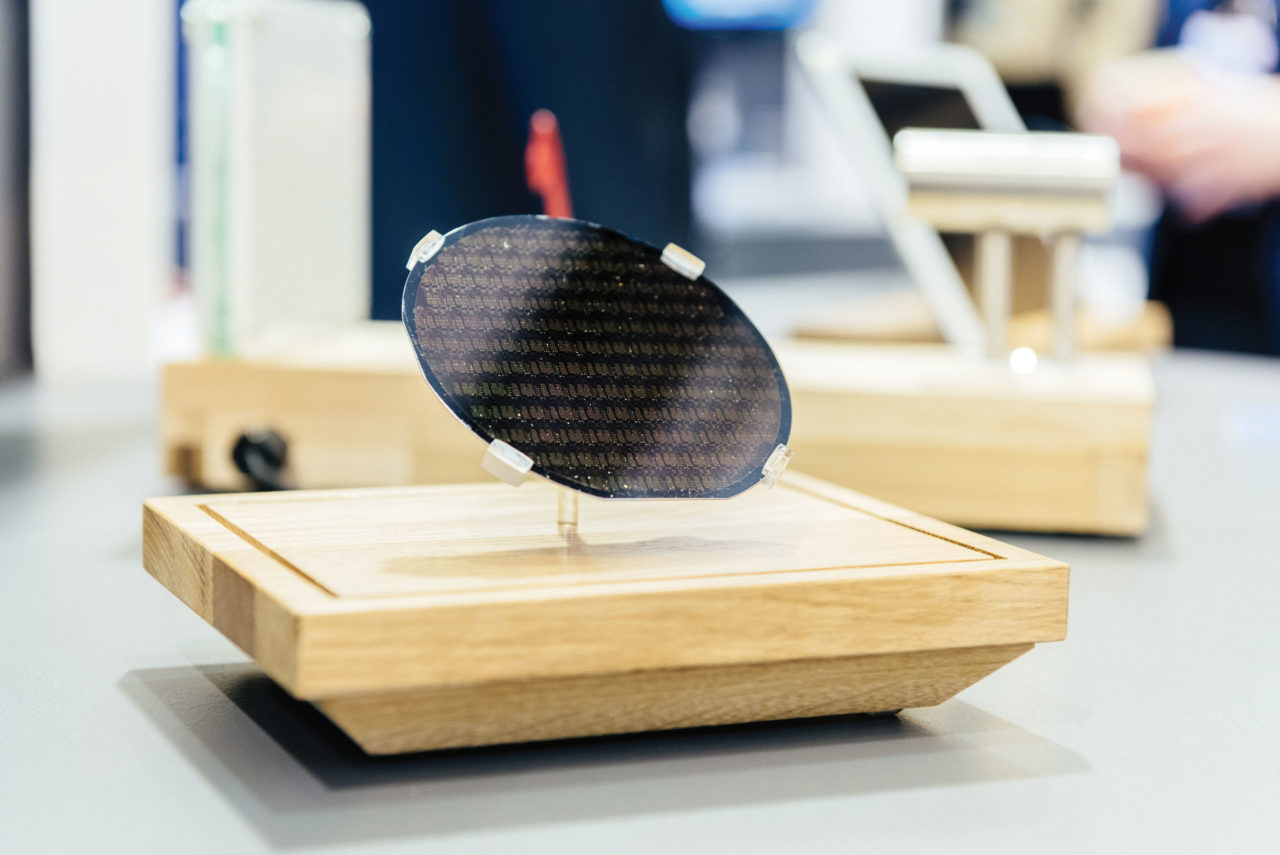

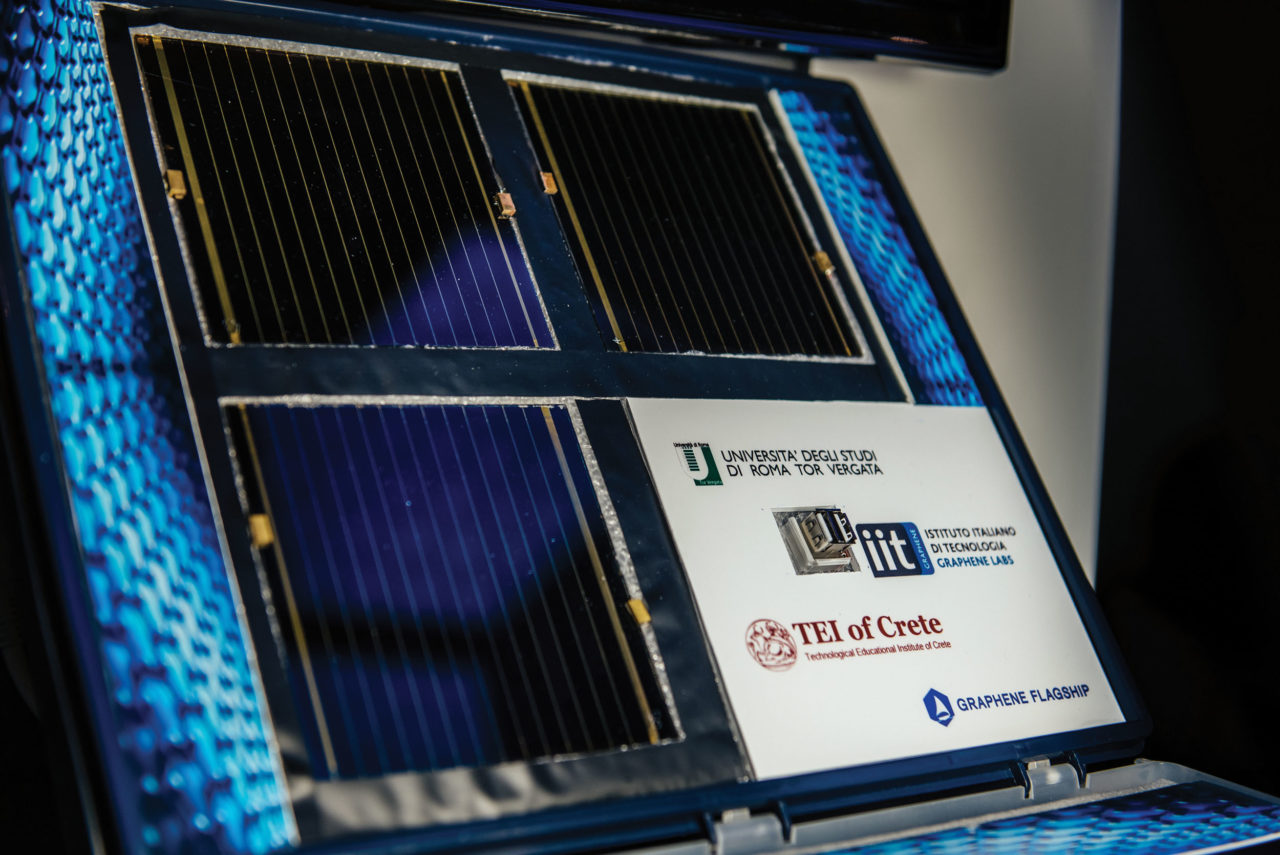

The good news is that researchers around the world are racing to get there. Last year, scientists at Massachusetts Institute of Technology made major strides toward developing a technique for producing consistently high-quality graphene sheets. Several hundred people are working on graphene-enhanced composite materials, like fiberglass rebar, at Oakridge National Lab in Knoxville, Tennessee. The United States, China, and other countries have federal initiatives funding research at companies and universities, because whoever develops technologies for producing graphene and practical uses for the material first will have a huge economic advantage. The E.U., for example, is funding a one-billion-euro initiative known as Graphene Flagship, a consortium of academics and industrial researchers aiming to bring applied uses of graphene into European society within the decade. While some private investors have been disappointed with the pace of development, many are still hoping to ride the wave of graphene-based products when they finally become available to the public.

Scientists have also made major progress in producing graphene flakes that can be incorporated into other materials. As a result, graphene-enhanced consumer products, like golf balls, sneakers, and eyeglass frames, have exploded onto the market in the past year. Barkan said that glass products and paving stones containing graphene—which promise extra strength and less color fading, respectively—are already available to the construction industry, even though manufacturers may not disclose it because they want to protect their formulas.

Another innovation that’s on the market now is graphene-enhanced paint. Earlier this year, the UK-based company Applied Graphene Materials announced an initial run of spray paint under the brand Hycote. The addition of graphene allows the coating—which is two to three times tougher than regular paint—to prevent rust.

The Ford Motor Company is already using graphene in its F-150 and Mustang cars. The company discovered that adding graphene to polyurethane created an engine cover that dissipated heat 30% more quickly than in previous models, while also reducing noise.

As more investment flows in, Barkan also warns about ensuring the quality of the products companies are promising. Graphene is a nanomaterial, undetectable to the human eye. The equipment to test the material costs over a million dollars.

“Unless you test what you have, you have no idea what’s in it,” Barkan said. “Consumers are at the mercy of the companies.”