-

February 26, 2021Four New York Teams Show the Passive House Path to Near-Zero-Carbon Building

Zack Semke, Director and Curator of Programming, Passive House Accelerator and moderator of the committee’s recent Research Practice Series: High Performance Homebuilders program, discusses the importance of Passive House residential design.

When Dennis Wedlick invited me to moderate the AIANY Custom Residential Architects Network’s January 26 program Research Practice Series: High-Performance Homebuilders, I jumped at the chance. It was a privilege to introduce the basic principles of Passive House design to the audience, introduce four pioneering single-family projects, and moderate a lively discussion between project teams. As director of Passive House Accelerator, I welcomed the opportunity to connect with AIANY members around a topic near and dear to my heart: how to decarbonize the building sector.

Passive House Accelerator is an independent, open-source, online platform that shares Passive House information, lessons-learned, and best practices to help designers and builders accelerate the adoption of deep energy efficiency in new builds and retrofits. Our aspiration is to serve as a catalyst for zero-carbon building. We publish articles, produce the Passive House Podcast, and present a steady stream of online events, including Passive House Accelerator Construction Tech every Tuesday and the Global Passive House Happy Hour every Wednesday, which Dennis presented at on Wednesday, February 17.

We’ve been doing these online events for nearly 50 weeks now, ever since COVID-19 lockdowns began. Well over 3,000 people have attended at least one program during that time and a dedicated core community of a few hundred has coalesced. We are seeing firsthand that interest in Passive House design and construction is on the rise.

WHY PASSIVE HOUSE?

So, why Passive House? This photo shows the interior of a Passive House retrofit designed by Michael Ingui of Baxt Ingui Architects, one of our January 26 panelists and a founder of Passive House Accelerator. When Michael talks with clients about the reasons for doing Passive House design, he doesn’t necessarily mention the term “Passive House”. Instead, he’ll ask his clients if they want a better building. Do they want a building that’s sealed off from dust and bugs and unwanted moisture and odors? Do they want an indoor environment of clean, fresh air? Do they want warm walls and floors so that they can walk around in bare feet even in the dead of winter? Do they want a structure that is quiet and peaceful, creating a serene indoor sanctuary?

Only then does Michael discuss the sustainability benefits of Passive House and the role that Passive House design and construction can play in addressing climate change.

And make no mistake, Passive House has a big role to play in climate action. We all know that we need to get to zero greenhouse gas emissions by 2050 or earlier, and that buildings make up at least 40% of the emissions problem. They are therefore also 40% of the solution. We need to decarbonize our buildings.

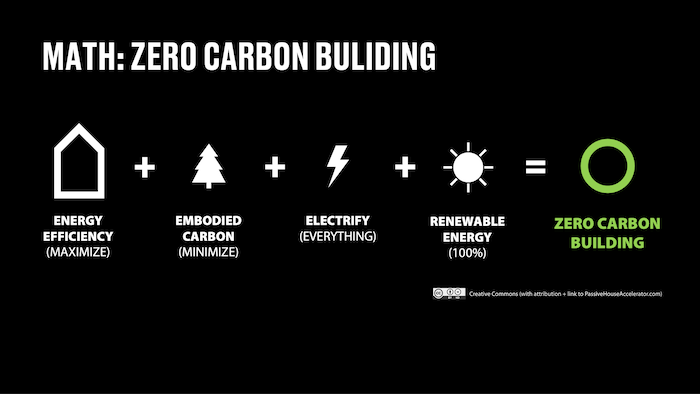

The math of zero-carbon building is fairly straight forward. First, we need to maximize energy efficiency. Then we need to minimize embodied carbon, electrify everything, and power it all with 100% renewable energy. There is no better way of reducing building energy consumption—of dramatically improving energy efficiency in a cost-effective and optimized way—than through Passive House design and construction. If you combine Passive House, low embodied carbon construction, electrification, and renewables, you can achieve zero-carbon building.

WHAT IS PASSIVE HOUSE?

The term “Passive House” is a bit of a misnomer in English; in the original German, “Passivhaus” means “passive building”. People are often surprised that Passive House design applies to all building types: schools, high-rise towers, institutional buildings, commercial spaces, and yes, single-family homes. Passive House buildings can also take on any style or shape, offering architects plenty of design flexibility. Passive House is about performance, not proscriptions.

Unlike checklist-based green building certifications like LEED, Passive House certification is focused on just three performance metrics based on good building science: heating and cooling demand (aka thermal energy demand intensity or TEDI), primary energy demand (aka energy use intensity or EUI), and air tightness.

In North America, there are two routes to Passive House certification for practitioners: the certification offer by the Passive House Institute (PHI) in Darmstadt, Germany and the certification offered by the Passive House Institute US (PHIUS) in Chicago. There are important differences between the two certifications (PHIUS has focused on modifying the three metrics based on the climate zone of any given project, for example), but both certifications share a focus on TEDI, EUI, and airtightness, and both employ a common suite of passive building design techniques to hit their ambitious performance targets.

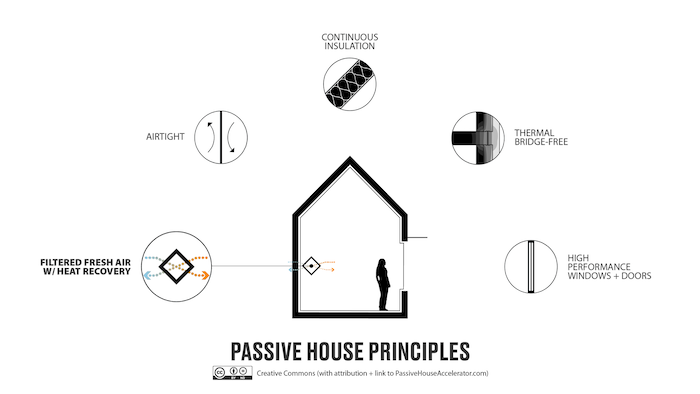

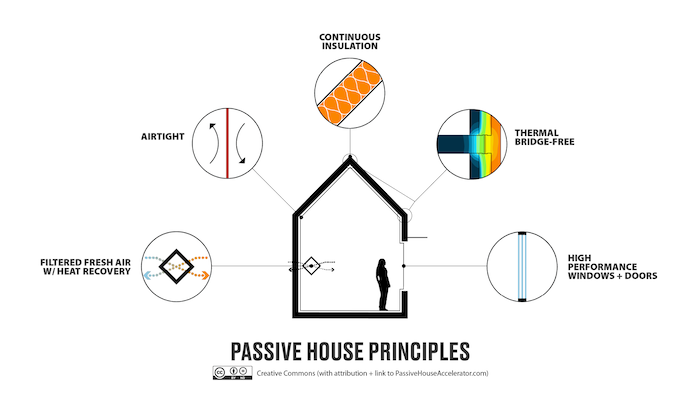

FIVE PASSIVE HOUSE PRINCIPLES

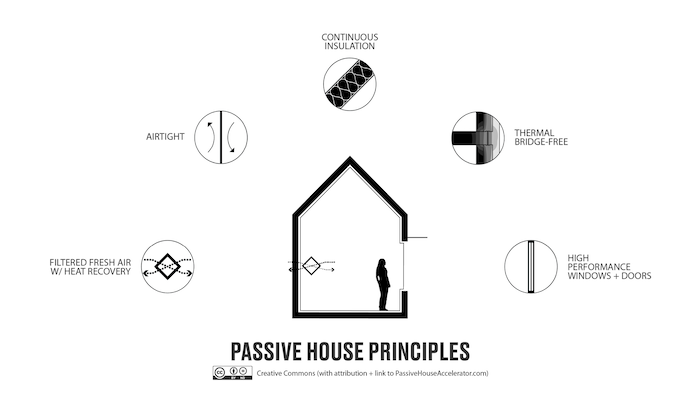

The classic way to explain Passive House design is through the “Five Passive House Principles”. (Note: the illustrations below are available to readers as part of a Creative Commons license, with attribution to Passive House Accelerator.)

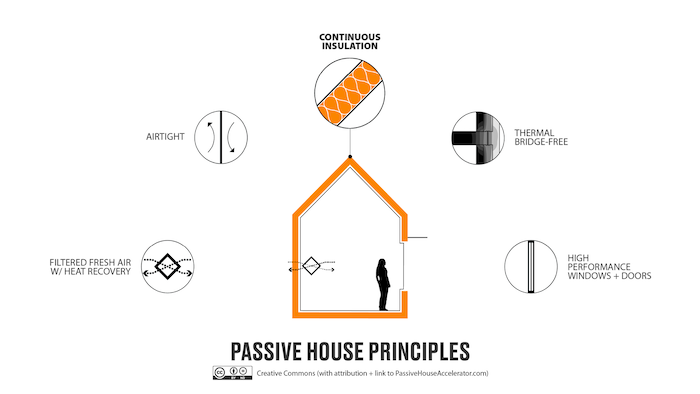

The first principle is to create a continuous layer of insulation around the building, wrapping it in a cozy sweater to keep it warm during the winter and cool during the summer.

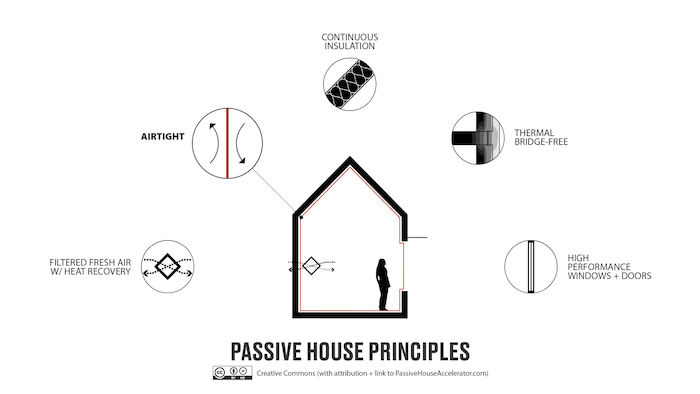

The second principle is to establish an uninterrupted air barrier around the building envelope, creating an unbroken “red line” of airtightness with tapes and membranes to seal off energy-sucking leaks (as well as the dust, bugs, and unwanted moisture that Michael discusses with his clients).

The third principle is to provide a constant supply of filtered, fresh air into the building with heat/energy recovery ventilation (H/ERV). H/ERV units transfer the heat energy from outgoing exhaust air into the incoming fresh air that is being taken into the building, all without the two airstreams ever mixing. The result is superior indoor air quality with almost no heat energy loss.

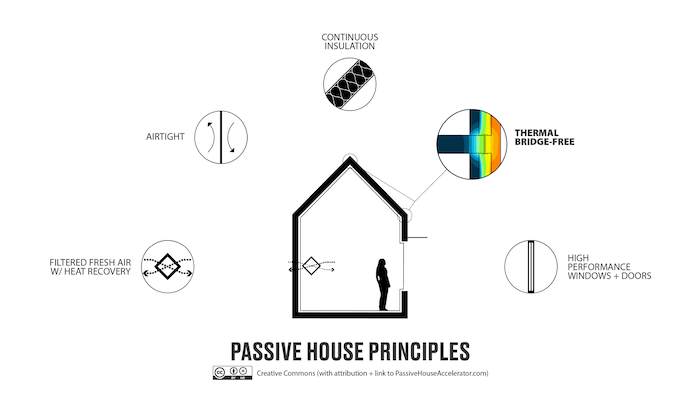

Fourth, we focus on thermal bridge-free design and construction. A common example of a thermal bridge is a concrete slab that extends from the interior to the exterior. Even the studs in an insulated exterior wall can become energy-sapping and moisture-inducing thermal bridges. Passive House designers create thermal breaks in building assemblies to avoid thermal bridges.

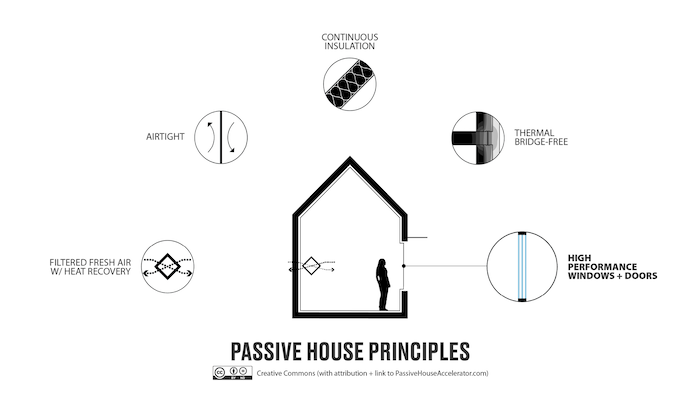

Fifth, we use high-performance windows and doors—typically triple glazed.

We bring all this together into a holistic solution using digital tools to optimize for both cost and performance.

As an architect, you don’t have to be a building physicist to harness the power of Passive House building science and Passive House design tools. If you are pursuing PHI certification, you’ll use the the Passive House Planning Package (PHPP) as your digital tool. If you are pursuing PHIUS certification, you’ll use Wufi-Passive. In either case, you or someone on your team will also likely take advantage of some of the suite of digital tools that help with thermal and hygrothermal analysis of assemblies, like Therm, Flixo, and Wufi.

THE FOUR VIDEO STORIES

With that Passive House intro under your belt, I encourage you to take in the four compelling video stories presented at the January 26 event. The first video stars Michelle Tinner and James Moriarty of Sustainable Comfort discussing an affordable, multi-family Passive House development. The second features Jen and Brian Marsh and builder Jason Endres talking about a single-family Passive House project. The third features Buck Morehead and Kevin Dunathan discussing their single-family project that got paused midstream but was then rescued by a new contractor. The final story features Michael Ingui and Andrew Fishman as they describe their ambitious Passive House retrofit of an historic masonry structure in New York City. They are all inspiring stories, each with a unique take on the application of the five Passive House principles in the real world and the emerging power of architects to dramatically reduce building energy use, and therefore operational carbon emissions. Let’s take their lead!

Custom Residential Architects Network

The Custom Residential Architects Network (CRAN) is a knowledge and networking community for AIANY members whose practice includes residential architecture and interior design. Committee programs explore innovation in practice, design, and construction techniques emerging from working on custom residential commissions, and introduce members to consultants and vendors who assist with residential projects. AIANY CRAN welcomes members from all industry sectors who are enthusiastic about custom architectural and interior residential commissions.